Over 50 years’ experience in researching materials management solutions makes OLI the ideal partner for all sector companies. A team of specialists is available to design and implement the most suitable solutions for each type of application and material on the market.

OLI analyses the overall problems, starting with the type of powder to manage, up to environmental conditions and process type. However, the client’s needs are always the centre of attention.

OLI’s global sales network assists clients at local level in over 50 countries ensuring deliveries of products are available directly from subsidiary warehouses.

Why use flow aids?

Due to their specific characteristics, many powder-based materials, when stored in silos, wagons, pipelines, tubing, tanks and other containers, tend to stick to the surface.

Every small change in outlet, a rough surface, bends, particularly narrow angles and physical properties of the materials can slow down product flow, thereby generating waste.

Flow aids are designed to solve problems caused by design errors or by the specific characteristics of the materials in powder or granules, thereby increasing process efficiency and improving system safety.

Olivibra Calculator: an online calculator for flow aids

To provide complete customer service, OLI has created an application with a step-by-step guide for product selection suitable for every project. What are the benefits of using our application?

- It is available online wherever the client might be

- It is updated in real time

- It is available in multiple languages

OLI PRODUCTS FOR Flow Aids

MVE-DC Direct current

The MVE DC electric vibrators consist of an electric motor housed in a robust cast aluminum casing designed by FMEA,...

MVE-SS Stainless Steel

The MVE-SS electric vibrating motors are equipped with an AISI 316 body, with a ""fluid"" design and are specifically...

VBT – Vibro aerators for silotrailers

The range of VBT vibro-aerators is the result of years of research and development that have led to the creation of a...

VBS – Vibro aerators for silos and hoppers

The range of VBS vibro-aerators is the result of years of research and development that have led to the creation of a...

F – Pneumatic adjustable piston vibrators

The pneumatic vibrators of the F range generate linear vibration thanks to the movement of a floating piston. To meet...

PG – Air cannons

PG air cannons prevents the formation of bridges and rat holes thanks to the high pressure air jet which is blown...

I100 – Fluidization pads

The I100 fluidizing plates are installed directly in contact with the material stored in the silo and are able to blow...

K – Pneumatic linear cushioned vibrators

In pneumatic vibrators K series, the vibration is generated by the linear movement of a floating piston (without impact...

PS – Hammers

The PS series hammers produce a high impact force thanks to a single impact between the internal piston and the metal...

MVO – Hydraulic vibrators

The MVO vibrator generates a high frequency rotational vibration thanks to a hydraulic system that activates an...

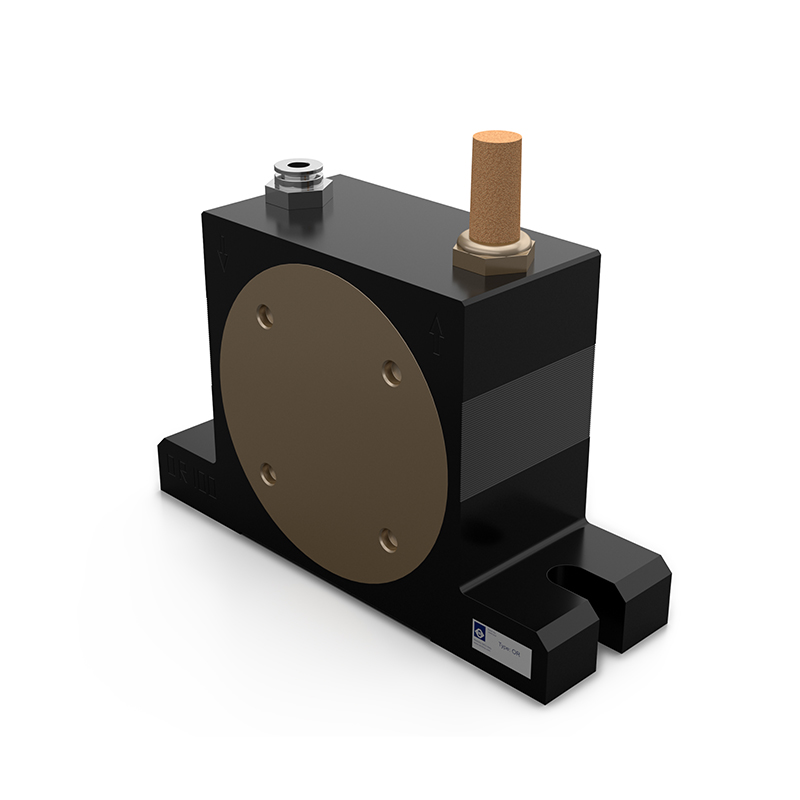

OR – Pneumatic rotational vibrators – roller

In the OR series, high frequency vibration is generated by a roller that describes an epicycloidal movement inside two...

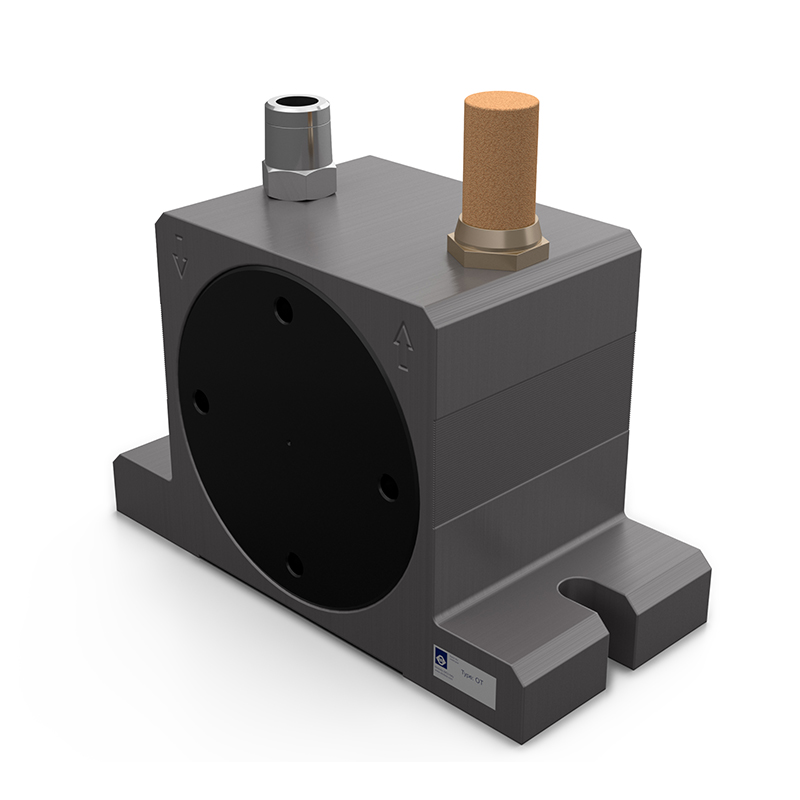

OT – Pneumatic rotational vibrators – turbine

The OT generate a high frequency vibration due to rotation at high speed of a turbine with integrated masses. Compared...

P – Continuous impact linear vibrators

The pneumatic vibrators of the P range produce an extremely high linear impact force. This is possible thanks to the...

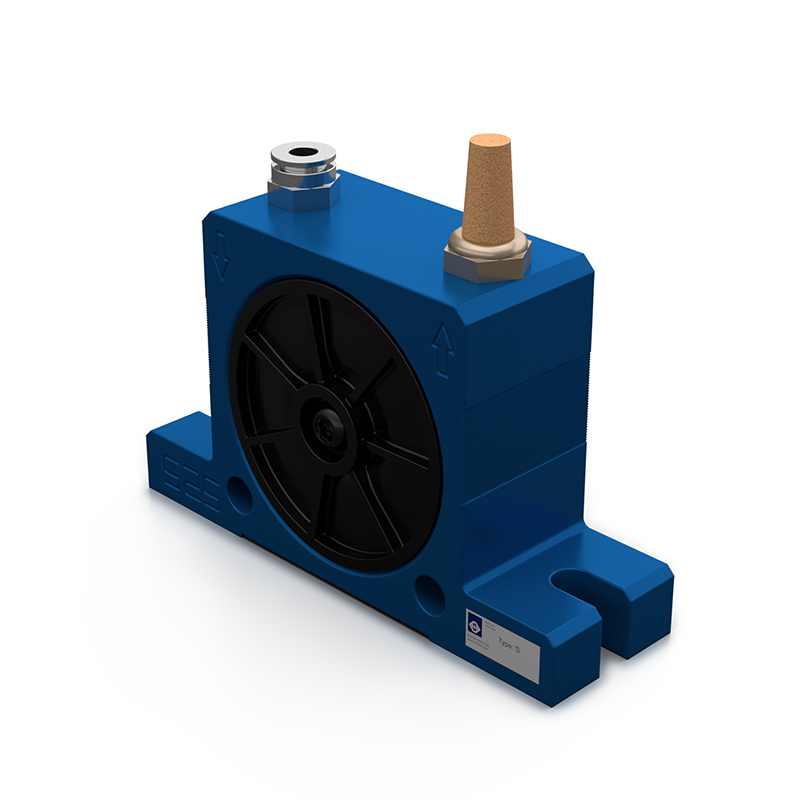

S – Pneumatic rotational vibrator – Ball

The OLI "S" series pneumatic rotational vibrators generate high frequency vibration thanks to a steel ball that rotates...

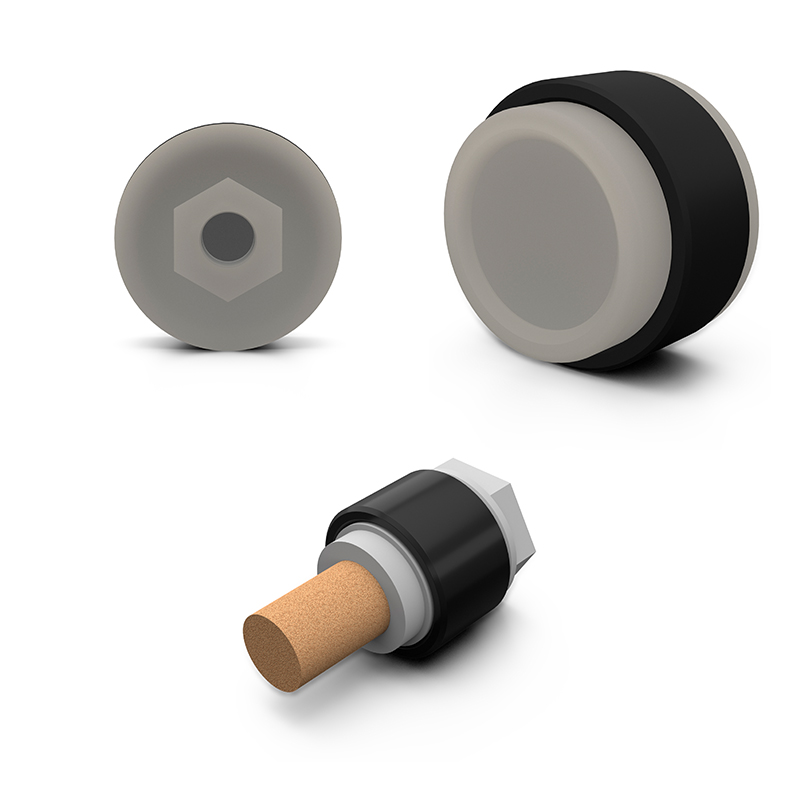

U – Fluidization nozzles

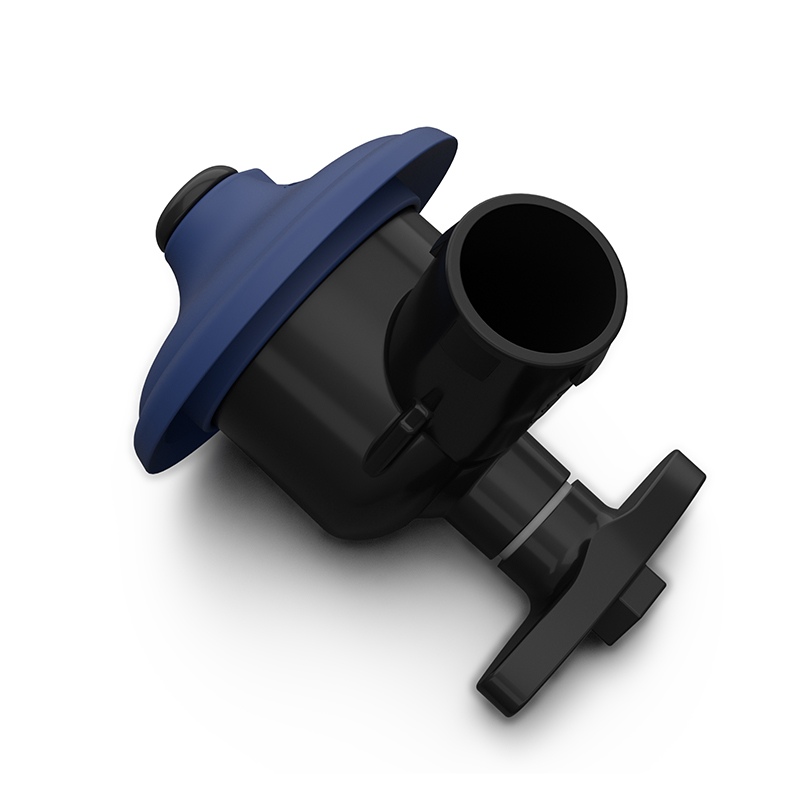

The fluidization nozzles U025 and U060 facilitate the flow of material into silos and hoppers thanks to a constant...

MOTOVIBRATOR FINDER

FLOW AIDS CALCULATOR

MOTOVIBRATOR FINDER

OLIVIBRA CALCULATOR