Every vibrating machine is different, OLI knows it.

We have been using vibration to move, sort, separate, and discharge material for more than 60 years.

Because of this, OLI is able to satisfy every customer’s needs,

from the mine to the mill, from the pharmaceutical industry to the foundry.

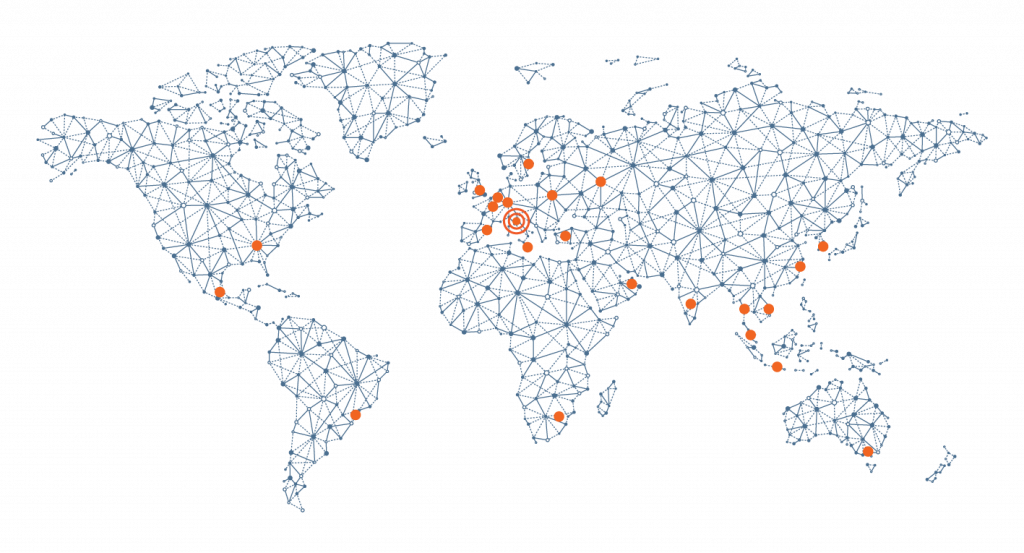

OLI: When you need it, where you need it.

The OLI line of industrial vibrators can be applied in a variety of industries, including construction, mining, the food industry, and recycling, in every nation on earth. Multiple voltages and up to 40,000 kg of centrifugal force can be produced by OLI electric vibrating motors.

Download the catalogue

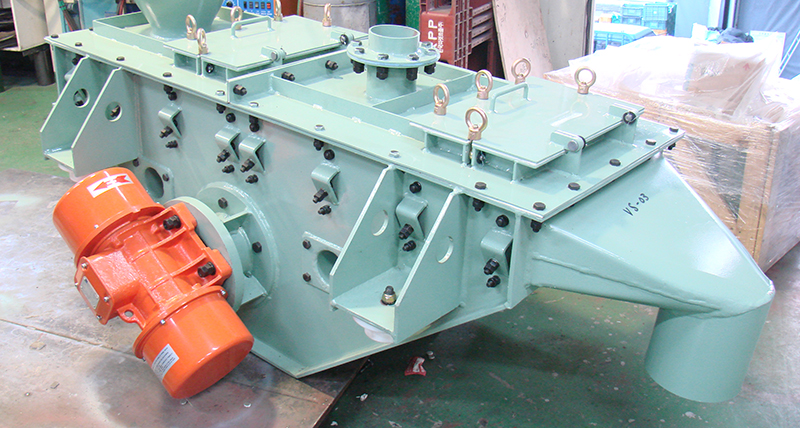

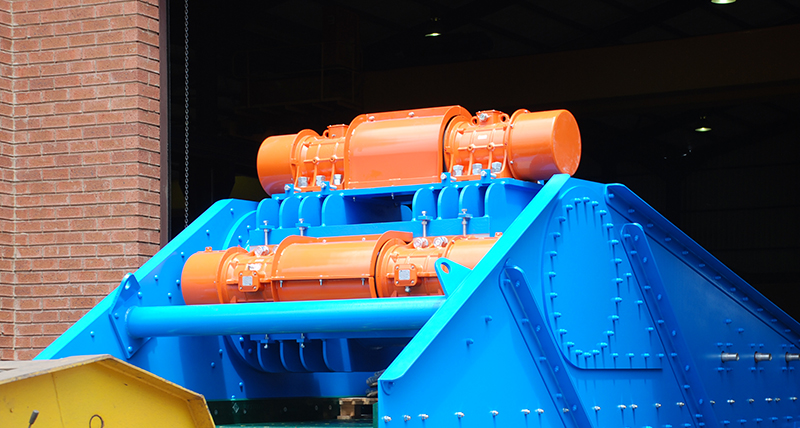

OLI’s vibrators can be used in a wide range of applications, including construction, mining, and manufacturing. They are designed to meet the needs of both large and small contractors, providing high performance.

OLI vibrators are built using the most modern technology, top-quality materials, and components. The assembly of the motor bodies, support flanges, and shafts, all of which were developed utilizing FMEA criteria, uses first-choice aluminum alloy, cast iron, and steel alloy. The vibrator can therefore be put on HEAVY-DUTY applications and still provide EXCELLENT PERFORMANCE and safety in every situation.

F class Vacuum-impregnated insulating materials have higher dependability and durability. Long-lasting performance and low noise are provided by reliable grease sealing and good BEARINGS. Additionally, the motor’s generated centrifugal force may be easily calibrated and adapted to each application thanks to the interchangeable eccentric masses.

Numerous certifications from OLI confirm that its products can be used in difficult conditions and can satisfy the most stringent global usage standards.